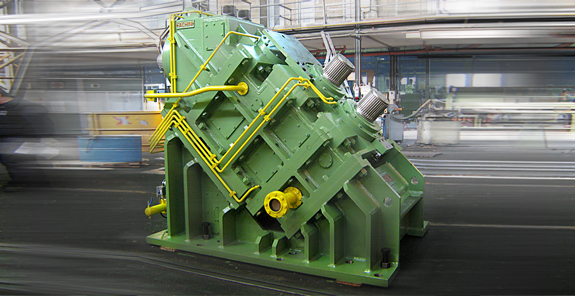

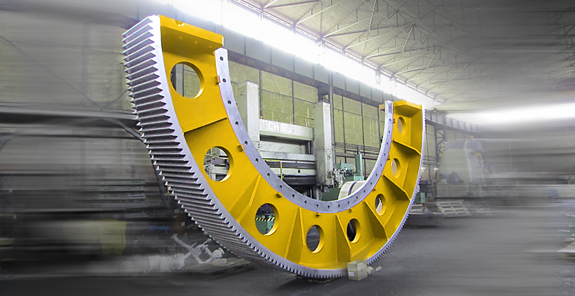

A ONE-STOP PRODUCTION PLANT – Our industrial plant extends over approximately 20,000 square metres and allows us to deal with all the stages involved in designing and manufacturing our transmission parts – speed reducers, gears, ring gears, pinions and couplings – in complete autonomy. A large technical department consisting of several engineers who work closely together assesses customers’ needs and presents the most suitable solutions which are then discussed with customers. Workshops then manufacture the product by performing all the production steps internally and special departments subject the transmission part to non-destructive testing, by applying mechanical stresses and tests using electronic devices. Finally, electronic testing is carried out on workbenches prior to delivery to the customer site and installation.